Scientists from the University of Nottingham’s School of Chemistry and Faculty of Engineering have developed a new coating for PA-12 polymer particles used in 3D printing, which not only significantly increases their functionality but also opens up new potential for new applications.

To do so, an efficient, effective, and clean process is created by supercritical carbon dioxide to coat PA-12 polymer particles, which is popular in a 3D printing process. The experiment also showed that the new coatings can add color and possess anti-mold and fungal characteristics during the printing process.

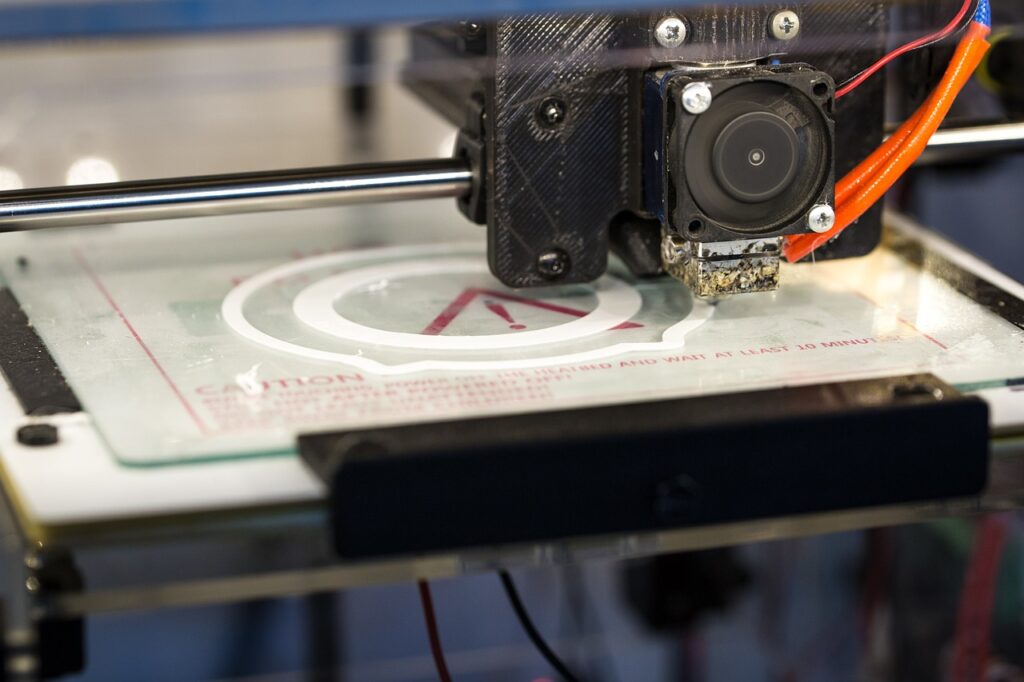

One of the most common 3D printing technologies is currently powder bed fusion or laser sintering, which processes polyamide-12 (PA12), a strong plastic often used in the 3D printing industry for printing complex and detailed parts.

It is commonly used in the automotive or aerospace fields. In this process, a layer of polymer powder is laid down and melted layer by layer using a laser designed and generated by a computer to guide. The layer is applied to a new layer of powder and the laser melts the powder together once again while simultaneously anchoring it to the layer below. This process works until the designed part is complete, often consisting of thousands of layers.

The significance of the new process is in its seamless integration with existing manufacturing processes. As so, by only aligning the mechanical and thermal properties of the coating with those of PA-12, the researchers can ensure compatibility with commercially deployed machines. This breakthrough not only can enhance the aesthetic appeal of printed objects but also broaden their functional capabilities.

Currently, the only options for manufacturers are gray or white powders, and the color is added afterward while the new process can deliver the addition of coatings for color. The team also has created various colored polymers to coat the PA-12 particles.

In addition, since objects made from PA-12 can’t be used in moist environments because of the growth of mold and fungi, the new coating can also address this issue. Therefore, it can open up new possibilities for the use of 3D-printed objects across various industries.

Article Source: University of Nottingham & Technology Network

Image by Lutz Peter from Pixabay